Understanding Screen Printing: A Comprehensive Guide

Screen printing, also known as silkscreen printing, is a versatile and widely used printing technique that involves transferring ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. This method is popular for its ability to produce vibrant colors and durable prints on a variety of materials, including textiles, ceramics, wood, paper, glass, and metal. The process has evolved over the years, incorporating new technologies and materials, but the fundamental principles remain largely unchanged.

The History of Screen Printing

Screen printing has a rich history that dates back to ancient China during the Song Dynasty (960–1279 AD). It was later adapted by other Asian countries, including Japan, where it was refined and developed further. The technique made its way to Europe in the late 18th century but gained significant popularity in the 20th century with the advent of synthetic materials and the development of commercial applications.

Early Beginnings

The earliest forms of screen printing involved the use of human hair stretched across a wooden frame to create a stencil. This primitive method was primarily used for printing patterns on fabric. As the technique spread across Asia, silk became the preferred material for the mesh, giving rise to the term "silkscreen printing."

Modern Advancements

In the 20th century, the introduction of photo-reactive chemicals revolutionized screen printing. This innovation allowed for the creation of more intricate and detailed stencils, expanding the possibilities for artists and commercial printers alike. The development of synthetic fibers for the mesh further enhanced the durability and precision of the prints.

The Screen Printing Process

The screen printing process involves several key steps, each crucial to achieving a high-quality print. These steps include preparing the screen, creating the stencil, setting up the printing station, and applying the ink.

Preparing the Screen

The first step in screen printing is preparing the screen, which involves stretching a fine mesh fabric over a frame. The mesh is then coated with a light-sensitive emulsion, which will harden when exposed to light. This creates a stencil that will block the ink in certain areas.

Creating the Stencil

Once the emulsion is dry, the screen is exposed to a light source with the desired image or design placed on top. The light hardens the emulsion in the exposed areas, while the areas covered by the design remain soft. The screen is then washed, removing the unhardened emulsion and leaving a clear stencil of the design.

Setting Up the Printing Station

With the stencil ready, the screen is placed on a printing press, and the substrate (such as a t-shirt or poster) is positioned beneath it. The screen is lowered onto the substrate, and ink is applied to the top of the screen.

Applying the Ink

A squeegee is used to push the ink through the mesh and onto the substrate. The ink passes through the open areas of the stencil, creating the desired image. Multiple screens can be used for multi-colored designs, with each color applied separately and allowed to dry before the next is added.

Applications of Screen Printing

Screen printing is renowned for its versatility and is used in a wide range of applications. From custom apparel and promotional products to fine art prints and industrial applications, the possibilities are virtually endless.

Textile Printing

One of the most common uses of screen printing is in the textile industry, where it is used to print designs on t-shirts, hoodies, and other garments. The technique is favored for its ability to produce vibrant, long-lasting prints that can withstand repeated washing.

Commercial and Industrial Uses

Beyond textiles, screen printing is used in various commercial and industrial applications. It is commonly employed to print labels, decals, and signage, as well as electronic circuit boards and other industrial components.

Artistic and Creative Applications

Artists and designers also utilize screen printing to create limited edition prints, posters, and other artworks. The technique allows for precise control over color and detail, making it a popular choice for fine art reproductions.

Advantages and Challenges of Screen Printing

Screen printing offers several advantages, including the ability to print on a wide range of materials and produce vibrant, durable prints. However, it also presents certain challenges, such as the need for specialized equipment and the time-consuming nature of the setup process.

Advantages

One of the primary advantages of screen printing is its versatility. The technique can be used on almost any surface, including fabrics, plastics, metals, and glass. Additionally, screen printing is capable of producing bold, opaque colors that are difficult to achieve with other printing methods.

Challenges

Despite its advantages, screen printing can be labor-intensive and requires a significant investment in equipment and materials. The process also involves multiple steps, each of which must be carefully executed to achieve the desired results. Furthermore, screen printing is not well-suited for small print runs, as the setup time and costs can be prohibitive.

Future Trends in Screen Printing

As technology continues to advance, the screen printing industry is poised for further innovation. Developments in digital printing technology and eco-friendly materials are expected to shape the future of the industry, offering new opportunities and challenges for screen printers.

Digital Integration

The integration of digital technology into traditional screen printing processes is one of the most significant trends in the industry. Hybrid printing systems that combine digital and screen printing capabilities are becoming increasingly popular, offering greater flexibility and efficiency.

Sustainability and Eco-Friendly Practices

As environmental concerns continue to grow, the screen printing industry is exploring more sustainable practices. This includes the use of water-based inks, biodegradable materials, and energy-efficient equipment to reduce the environmental impact of the printing process.

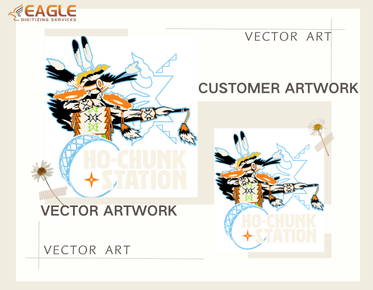

In conclusion, screen printing remains a vital and dynamic printing method with a rich history and a promising future. Whether used for commercial, industrial, or artistic purposes, the technique continues to evolve, offering new possibilities for creativity and innovation. For those interested in exploring the world of screen printing, Eagle Digitizing excels in delivering professional vector art services, transforming creative visions into scalable designs.