Key to Enhancing Productivity: The Application of Embroidery Services and Vector Art Design in the Manufacturing Industry

In the ever-evolving landscape of the manufacturing industry, businesses are constantly seeking innovative ways to enhance productivity and streamline operations. One such avenue that has gained significant traction is the integration of embroidery digitizing services. This technological advancement not only revolutionizes the way designs are created but also plays a pivotal role in boosting efficiency and reducing production time.

The Role of Embroidery Services in Manufacturing

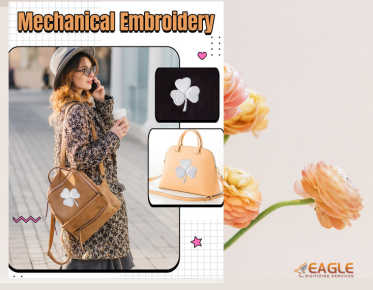

Embroidery services have long been associated with the fashion and textile industries, but their application in manufacturing extends far beyond traditional boundaries. By leveraging advanced embroidery machines and digitizing software, manufacturers can produce intricate designs with unparalleled precision. This capability is particularly beneficial in sectors where branding and customization are paramount, such as automotive interiors and corporate apparel.

Precision and Customization

The precision offered by modern embroidery machines allows for the creation of complex patterns and logos that were once deemed impossible. This level of detail is crucial for maintaining brand integrity and ensuring that every product meets the highest standards of quality. Moreover, the ability to customize designs on-demand enables manufacturers to cater to niche markets and respond swiftly to changing consumer preferences.

Vector Art Design: A Complementary Tool

Alongside embroidery services, vector art design has emerged as a complementary tool that enhances the overall design process. Vector graphics are essential for creating scalable and editable designs that maintain their quality across various mediums. This is particularly important in manufacturing, where designs need to be adapted for different product sizes and materials.

Scalability and Versatility

Vector art design offers unparalleled scalability, allowing manufacturers to resize designs without compromising on quality. This versatility is crucial in industries such as packaging and promotional products, where designs must be adapted to fit different formats. By integrating vector art design into their workflow, manufacturers can ensure consistency and accuracy across all production stages.

Enhancing Productivity Through Technology

The integration of embroidery services and vector art design into the manufacturing process is a testament to the power of technology in enhancing productivity. By automating design creation and reducing manual intervention, manufacturers can significantly cut down on production time and costs. This not only improves operational efficiency but also allows businesses to allocate resources more effectively.

Automation and Efficiency

Automation is a key driver of productivity in the manufacturing industry. By utilizing embroidery digitizing software, manufacturers can automate the conversion of designs into machine-readable formats, eliminating the need for manual input. This streamlines the production process and minimizes the risk of errors, resulting in higher output and improved product quality.

Future Trends in Manufacturing Design

As technology continues to evolve, the future of manufacturing design looks promising. The integration of artificial intelligence and machine learning into embroidery and vector art design is set to revolutionize the industry further. These advancements will enable manufacturers to predict design trends, optimize production schedules, and enhance quality control measures.

In conclusion, the application of embroidery services and vector art design in the manufacturing industry is a key driver of productivity and innovation. By embracing these technologies, businesses can stay ahead of the competition and meet the ever-changing demands of the market. Eagle Digitizing excels in providing professional embroidery digitizing services, ensuring every design is crafted with unmatched precision. As the industry continues to evolve, manufacturers must remain agile and open to new possibilities to thrive in this dynamic landscape.