The Essential 10 Steps in Silk Screen Printing

html

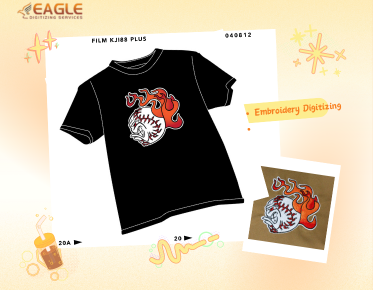

Silk screen printing, also known as serigraphy, is a versatile and popular method for creating vibrant prints on various materials. Whether you're a beginner or a seasoned professional, understanding the fundamental steps involved in silk screen printing is crucial for achieving high-quality results. In this guide, we'll explore the ten essential steps in silk screen printing, providing insights and tips to enhance your printing projects. For more detailed information on silk screen printing, you can check out this comprehensive video tutorial【4:0†source】.

1. Designing the Artwork

The first step in silk screen printing is creating or selecting the artwork you want to print. This design will be transferred onto the screen, so it's essential to ensure that the artwork is clear and suitable for the printing process. Many artists use digital tools to create vector graphics, which are ideal for screen printing due to their scalability and precision.

2. Preparing the Screen

Once the artwork is ready, the next step is to prepare the screen. This involves stretching a fine mesh fabric over a frame, typically made of wood or aluminum. The mesh is then coated with a light-sensitive emulsion, which will harden when exposed to light, creating a stencil of your design.

3. Exposing the Screen

After the emulsion has dried, the screen is exposed to a light source with the artwork placed on top. The light hardens the emulsion except where the design blocks it, leaving a stencil of the artwork on the screen. This step requires precision and timing to ensure the stencil is accurately created.

4. Washing Out the Screen

Once the exposure is complete, the screen is washed with water to remove the unhardened emulsion, revealing the stencil. This step requires careful handling to avoid damaging the stencil. The screen is then left to dry completely before proceeding to the next step.

5. Setting Up the Printing Station

With the screen ready, it's time to set up the printing station. This involves securing the screen onto a printing press or a flat surface, aligning it with the material to be printed on, and ensuring that everything is stable and properly positioned.

6. Mixing the Ink

Choosing the right ink is crucial for achieving the desired print quality. Screen printing inks come in various types, including water-based, plastisol, and discharge inks. Mixing the ink to the right consistency and color is essential for vibrant and durable prints.

7. Printing the Design

With the screen and ink ready, the actual printing process begins. Ink is applied to the screen, and a squeegee is used to press the ink through the stencil onto the material. This step requires a steady hand and consistent pressure to ensure even ink distribution.

8. Curing the Ink

After printing, the ink must be cured to set it permanently onto the material. This is typically done using a heat source, such as a conveyor dryer or a heat press. Proper curing ensures that the print is durable and resistant to washing and wear.

9. Cleaning the Screen

Once the printing is complete, the screen must be cleaned thoroughly to remove any remaining ink and emulsion. This step is crucial for maintaining the screen's longevity and ensuring it can be reused for future projects.

10. Quality Control and Finishing

The final step in silk screen printing is quality control. Inspect the printed materials for any imperfections or inconsistencies. Make any necessary adjustments and apply finishing touches, such as trimming or packaging, to complete the project.

Silk screen printing is a rewarding process that combines creativity and technical skill. By following these ten essential steps, you can achieve professional-quality prints that stand out. As the industry evolves, new techniques and technologies continue to enhance the capabilities of silk screen printing. For those looking to expand their skills, exploring vector graphics can offer new possibilities in design and printing【4:0†source】. Eagle Digitizing excels in delivering professional vector art services, transforming creative visions into scalable designs. What innovative trends do you foresee shaping the future of silk screen printing?