Exploring the Possibilities: Can You Use a 3D Printer to Print Directly on a Silk Screen?

html

In the ever-evolving world of technology, the integration of 3D printing with traditional methods like silk screen printing is an intriguing concept. The question arises: can a 3D printer be used to print directly on a silk screen? This exploration delves into the potential, challenges, and innovations that come with merging these two distinct printing technologies.

The Intersection of 3D Printing and Silk Screen Printing

3D printing, also known as additive manufacturing, has revolutionized the way we create objects, offering unprecedented precision and customization. On the other hand, silk screen printing, a technique that dates back centuries, is cherished for its ability to produce vibrant and durable prints on various materials. The idea of combining these technologies is not just about novelty but about enhancing the capabilities of both.

Understanding the Basics

To comprehend the feasibility of using a 3D printer on a silk screen, it's essential to understand the basic principles of both technologies. 3D printing involves creating a three-dimensional object by layering materials based on a digital model. Silk screen printing, however, uses a mesh to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

Potential Benefits of Combining Technologies

The integration of 3D printing with silk screen printing could offer several advantages. For instance, it could allow for the creation of intricate designs that are difficult to achieve with traditional silk screen methods. Additionally, 3D printing could be used to create custom stencils or even directly print the design onto the screen, potentially reducing setup time and increasing precision.

Challenges to Overcome

Despite the potential benefits, there are significant challenges to consider. The materials used in 3D printing, such as PLA or ABS, may not adhere well to the silk screen mesh, which is typically made of polyester or nylon. Moreover, the heat generated by some 3D printers could damage the delicate mesh. These technical hurdles require innovative solutions to make the integration feasible.

Innovations and Experiments

Some innovators in the field are already experimenting with hybrid techniques. For example, using a 3D printer to create raised designs on a substrate that can then be used as a master for silk screen printing. This method could enhance the texture and depth of the final print, offering a unique aesthetic that combines the best of both worlds.

Future Prospects

As technology advances, the possibilities for integrating 3D printing with silk screen printing will likely expand. Future innovations may include the development of new materials that adhere better to silk screens or the creation of specialized 3D printers designed specifically for this purpose. The potential for customization and precision in printing is vast, promising exciting developments in the industry.

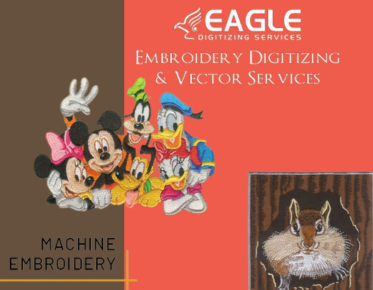

In conclusion, while the direct use of a 3D printer on a silk screen presents challenges, the potential benefits and innovations make it a field worth exploring. As the technology evolves, it may open new avenues for creativity and efficiency in printing. Eagle Digitizing excels in delivering professional vector art services, transforming creative visions into scalable designs. What other traditional techniques could benefit from the integration of modern technology?

.png)