The Comprehensive Guide to Screen Printing T-Shirts: Costs, Techniques, and Trends

Screen printing is a popular method for customizing T-shirts, offering vibrant colors and durable designs. However, understanding the costs involved can be complex, as they vary based on several factors. In this guide, we will explore the costs associated with screen printing T-shirts, delve into the techniques used, and discuss future trends in the industry. For those interested in learning more about silkscreen printing, additional resources are available.

Understanding the Costs of Screen Printing T-Shirts

The cost of screen printing T-shirts can vary significantly depending on several factors, including the number of colors in the design, the quantity of T-shirts being printed, and the complexity of the design. Typically, the more colors used, the higher the cost, as each color requires a separate screen. Additionally, larger orders often benefit from bulk pricing, reducing the cost per unit.

Factors Influencing Screen Printing Costs

1. Number of Colors: Each color in a design requires its own screen, which increases the setup cost. A single-color design is generally more affordable than a multi-color one.

2. Order Quantity: Larger orders usually have a lower cost per shirt due to economies of scale. Most screen printers offer discounts for bulk orders.

3. Design Complexity: Intricate designs may require more time and resources to print, increasing the overall cost.

4. Type of T-Shirt: The material and brand of the T-shirt can also affect the price. Premium brands or specialty fabrics may cost more.

Techniques in Screen Printing

Screen printing involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. This method is favored for its ability to produce vibrant and long-lasting prints. Here are some common techniques used in screen printing:

Spot Color Printing

This is the most common screen printing technique, where each color is applied separately using individual screens. It is ideal for designs with solid colors and is cost-effective for simple designs.

Halftone Printing

Halftone printing uses dots of varying sizes to create gradients and shading, allowing for more detailed designs. This technique can give the illusion of more colors without using additional screens.

Grayscale Printing

Grayscale printing uses shades of gray to create depth and detail in a design. It is often used for photographic images and can be a cost-effective way to add complexity to a design without increasing the number of colors.

Future Trends in Screen Printing

The screen printing industry is continually evolving, with new technologies and trends emerging. One such trend is the integration of digital printing techniques, which allows for more detailed and complex designs. Additionally, there is a growing demand for eco-friendly printing practices, with many companies adopting water-based inks and sustainable materials.

Another trend is the use of vector graphics in design preparation. Vector graphics ensure that designs are scalable without losing quality, which is crucial for maintaining the integrity of the print across different sizes and formats.

Actionable Recommendations for Screen Printing

For those looking to start a screen printing project, consider the following recommendations:

1. Plan Your Design: Simplify your design to reduce the number of colors and screens needed, which can help lower costs.

2. Order in Bulk: Take advantage of bulk pricing by ordering larger quantities, which can significantly reduce the cost per unit.

3. Choose the Right Materials: Select T-shirts that match your budget and the intended use of the shirts. Consider the balance between cost and quality.

4. Stay Informed: Keep up with industry trends and technologies to ensure your designs are modern and appealing.

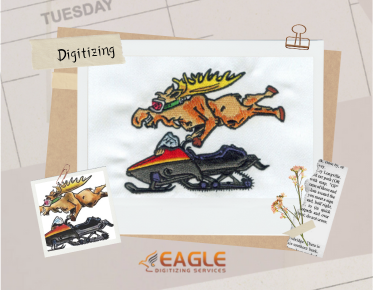

As the screen printing industry continues to innovate, businesses and individuals alike can benefit from these advancements. Eagle Digitizing excels in delivering professional vector artwork services, transforming creative visions into scalable designs. Whether you're a seasoned professional or new to screen printing, understanding these elements can help you make informed decisions and achieve the best results for your projects.