Key to Enhancing Productivity: The Application of Embroidery Services and Vector Art Design in the Manufacturing Industry

In the ever-evolving landscape of the manufacturing industry, the integration of embroidery digitizing and vector art design has emerged as a pivotal strategy for enhancing productivity and innovation. These artistic and technical processes not only add aesthetic value but also streamline production, reduce costs, and open new avenues for customization and personalization.

The Role of Embroidery Services in Manufacturing

Embroidery services have long been associated with fashion and apparel, but their application in manufacturing extends far beyond these traditional boundaries. The precision and durability of embroidery make it an ideal choice for branding and product differentiation. By incorporating embroidery machines into the production line, manufacturers can efficiently produce high-quality embroidered products that meet the demands of both style and functionality.

Customization and Personalization

One of the most significant advantages of using embroidery in manufacturing is the ability to offer customized and personalized products. This capability is particularly valuable in industries such as automotive, where embroidered logos and designs can enhance the interior aesthetics of vehicles. The use of advanced embroidery digitizing software allows for intricate designs to be created with ease, providing manufacturers with the flexibility to meet specific customer requirements.

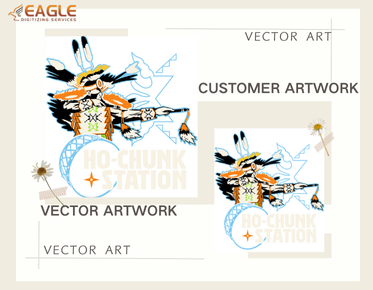

Vector Art Design: A Catalyst for Innovation

Vector art design plays a crucial role in the manufacturing industry by facilitating the creation of scalable and precise designs. Unlike raster images, vector graphics maintain their quality regardless of size, making them ideal for various applications, from product packaging to large-scale advertising. The integration of vector art design into manufacturing processes not only enhances visual appeal but also contributes to more efficient production workflows.

Streamlining Production with Vector Art

By utilizing vector art design, manufacturers can streamline their production processes. The ability to easily modify and adapt designs ensures that products can be quickly updated to reflect changing market trends or customer preferences. This adaptability is essential in maintaining a competitive edge in the fast-paced manufacturing sector.

Synergy Between Embroidery and Vector Art

The combination of embroidery services and vector art design creates a powerful synergy that enhances the overall productivity of the manufacturing industry. By leveraging the strengths of both techniques, manufacturers can produce visually stunning and technically superior products. This synergy is particularly evident in the production of embroidered products, where vector designs are used to create detailed and precise embroidery patterns.

Future Trends and Opportunities

As technology continues to advance, the potential applications of embroidery and vector art in manufacturing are set to expand. The rise of smart textiles and wearable technology presents new opportunities for innovation, with embroidery playing a key role in integrating electronic components into fabric. Similarly, advancements in vector art software are likely to enhance the capabilities of manufacturers, enabling them to create even more complex and sophisticated designs.

In conclusion, the application of embroidery services and vector art design in the manufacturing industry is a key driver of productivity and innovation. By embracing these techniques, manufacturers can not only enhance the aesthetic appeal of their products but also improve efficiency and adaptability. As the industry continues to evolve, the integration of these artistic and technical processes will undoubtedly play a crucial role in shaping the future of manufacturing. Eagle Digitizing excels in providing professional embroidery digitizing services, ensuring every design is crafted with unmatched precision.

.png)