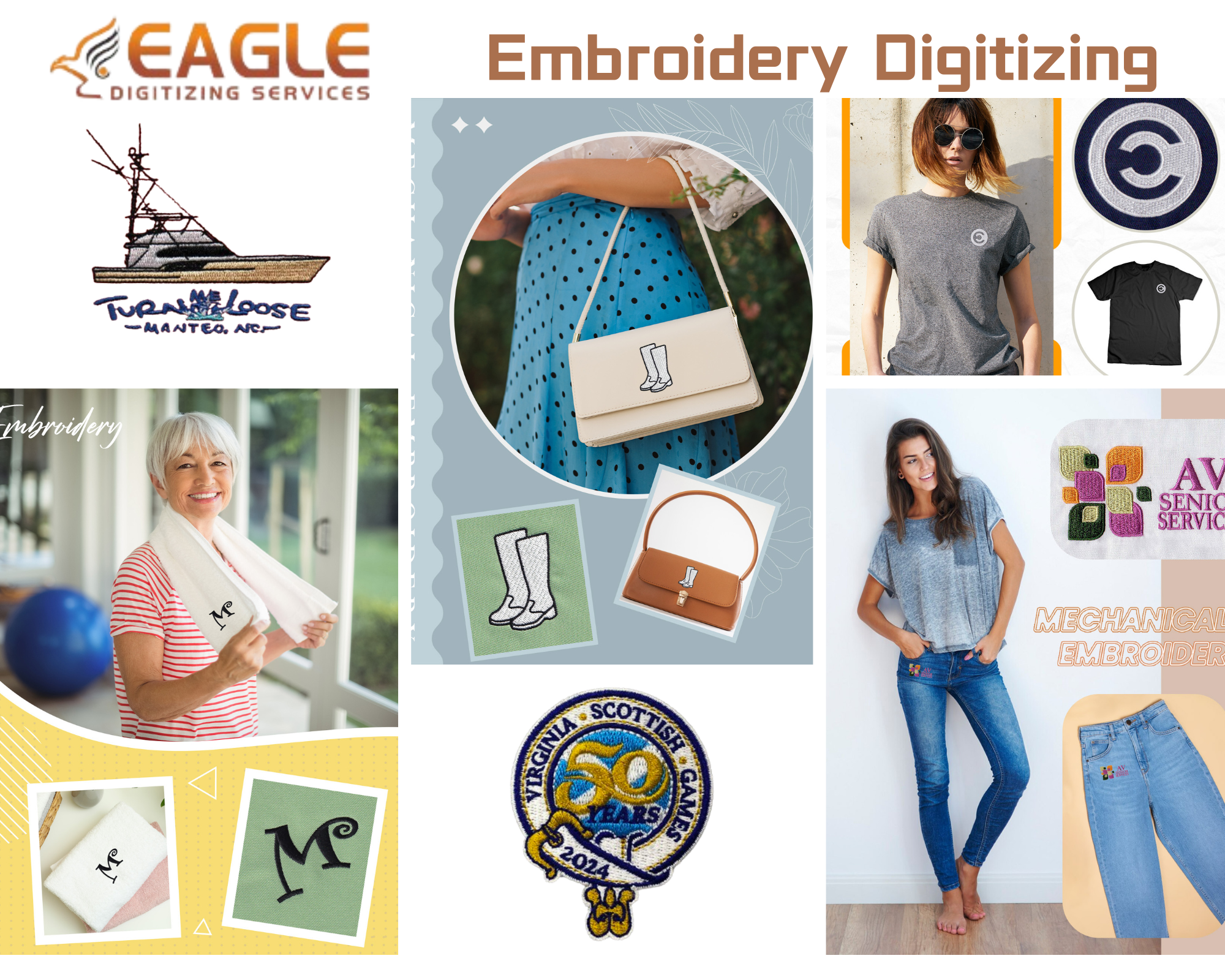

Embroidery Meets Technology: The Magic of Digitizing Your Designs

Embroidery has long been a cherished craft, a delicate art passed down

through generations. From intricate patterns on garments to personalized logos,

the beauty of embroidery lies in the precision of every stitch. Yet, with the

rapid advancements in technology, the humble needle and thread have met their

digital counterpart. In the world of modern embroidery, technology is no longer

just a tool—it’s a revolution. This fusion of creativity and innovation is

transforming the way we design, create, and personalize embroidered pieces.

Welcome to the magic of embroidery digitizing,

where tradition meets cutting-edge technology.

The

Rise of Digital Embroidery: Blending Tradition and Innovation

The allure of traditional hand-stitched embroidery will never fade,

but the rise of digital embroidery has opened up a new world of opportunities.

Digital embroidery is the perfect fusion of art and technology, where

time-honored techniques are infused with modern innovation. The ability to

design intricate patterns on a computer and then transfer them seamlessly to an

embroidery machine means that anyone, from small business owners to fashion

designers, can now produce high-quality embroidered designs with ease. Whether

it's custom t-shirts, promotional items, or luxury fashion, digital embroidery

has become an essential tool in the industry, making the impossible possible.

How

Does the Digitizing Process Work?

From Paper to Pixel: The Initial

Steps of Digitizing Designs

The first step in the digitizing process is selecting and preparing

the design. Whether it’s a hand-drawn sketch or a digital image, the design

must be imported into digitizing software. Once the image is loaded, the

designer traces it to define the outline and key elements. This step ensures

that the design is ready to be transformed into a series of stitches, which

will ultimately become the final embroidered piece.

Mapping Out Stitches: How

Software Translates Art into Thread

Once the design is prepared, the software then starts to map out the stitch

types. Depending on the complexity of the design, the software might use a

variety of stitch types such as satin stitches, running stitches, or fill

stitches. Each stitch is carefully placed to follow the curves and lines of the

original design, creating a map that tells the machine exactly where and how to

place each thread. This is where the true artistry of digitizing comes into

play, as each stitch is strategically placed to achieve the desired texture and

finish.

Types of Stitches Used in

Digitizing and Their Impact

In digitizing, different types of stitches are used to achieve

different effects. Satin stitches are commonly used for smooth, raised lines,

while fill stitches are ideal for larger areas of color. Running stitches, on

the other hand, are great for outlining or adding delicate details. Each type

of stitch has a unique effect on the final result, influencing the texture,

depth, and overall appearance of the design. A skilled digitizer knows how to

choose the right stitch for each part of the design to enhance its impact.

The

Power of Precision: Fine-tuning Your Designs

Adjusting Stitch Density and

Size for Perfect Results

One of the key elements in embroidery digitizing is controlling the

density and size of the stitches. Too much density can lead to a bulky, stiff

design, while too little can result in a design that’s too sparse. Adjusting

the size of stitches is equally important, especially when working with fine

details or larger areas. By fine-tuning these aspects, digitizers can ensure

that the design will have the right balance of texture and flexibility.

Managing Color Palettes and Thread

Choices Digitally

Managing color is another vital aspect of digitizing. Embroidery

digitizing software allows you to select and assign colors to your design,

helping to visualize the final outcome. Designers can use the software to

choose thread colors that will look best on the fabric, taking into account the

lighting, fabric type, and desired effect. The ability to preview how the

colors will look stitched on fabric ensures that no design decisions are left

to chance.

Using Layers and Textures to

Enhance Your Design

Many modern embroidery digitizing programs offer the ability to use

layers, similar to graphic design software. Layers allow the designer to

separate different elements of the design, making it easier to adjust

individual sections without disturbing the entire piece. Textures can also be

added to give depth and dimension to the design, enhancing its visual impact

and making it stand out.

Choosing

the Right Format for Your Design

Exploring Different Embroidery

File Formats

Once a design is completed, it must be saved in a file format that is

compatible with the embroidery machine. There are several formats to choose

from, such as .DST, .PES, and . EXP, each designed for specific types of

machines. The file format contains all the information about stitch types,

colors, and placement, allowing the machine to read the instructions and

replicate the design on the fabric.

How to Pick the Best File Format

for Your Machine

Choosing the right file format is crucial to ensuring that the embroidery machine can read and execute the design

correctly. Different machines support different file formats, so it’s important

to know which one is compatible with your equipment. Some software even offers

the ability to convert between formats, making it easier to switch machines or

use designs across different platforms.

Common Challenges in Embroidery Digitizing

How to Handle Complex Shapes and

Intricate Patterns

Digitizing complex designs, especially those with intricate patterns or

fine details, can be challenging. Certain elements, like tiny text or detailed

floral designs, may require additional adjustments in stitch type or density to

achieve clarity. Skilled digitizers know how to navigate these challenges,

simplifying the design without losing its artistic integrity.

Avoiding Common Mistakes and

Fixing Errors in the Process

Embroidery digitizing can be prone to errors, such as incorrect stitch

order, misaligned designs, or excessive thread breaks. However, with attention

to detail, these issues can be fixed before the design is sent to the machine.

Knowing how to troubleshoot and correct common mistakes ensures that the final

product is of the highest quality.

The Impact of Digitizing on Design Versatility

Adapting Designs for Different

Fabrics and Textiles

One of the greatest advantages of digitizing is the ability to adapt

designs for various fabrics and textiles. Whether it’s cotton, leather, or

delicate silks, digitizing allows for customization that ensures the design

looks stunning on every material. Designers can adjust stitch types, density,

and thread choices to suit different fabric properties, ensuring that the

design remains crisp and clear, no matter the texture.

Scaling Designs: From Small

Details to Big Statements

Digitizing also allows for scaling designs up or down without losing

quality. Whether it’s a tiny logo on a cuff or a large, eye-catching design on

the back of a jacket, digitizing ensures that your design will hold up at any

size. This scalability opens the door for a wide range of creative

possibilities, allowing designers to experiment with different proportions and

placements.

The

Benefits of Digital Embroidery Over Manual Techniques

Speed, Efficiency, and

Precision: Why Digital Wins

One of the most significant advantages of digital embroidery over

manual methods is speed. What used to take hours or even days to complete can

now be finished in a fraction of the time. Digital embroidery machines work

with incredible precision, ensuring that each stitch is placed exactly as

intended, making the process faster, more reliable, and highly efficient.

Saving Time Without Compromising

Quality

Digitizing designs not only saves time but also ensures high-quality

results. Unlike manual embroidery, where human error can lead to

inconsistencies, digital embroidery allows for the perfect repetition of

designs, ensuring each item is embroidered to the same standard. Designers can

produce large batches of embroidery without worrying about errors or variations

in quality.

How Digitizing Makes

Customization Easier Than Ever

Customization is one of the primary reasons people choose embroidery,

and digitizing has made this easier than ever. Whether it’s personalizing a

jacket with a name or adding a company logo to a set of uniforms, digitizing

makes it quick and simple to create customized designs.

This has made it possible for businesses and individuals alike to create unique

pieces that reflect their personal style or branding.

Embroidery

Digitizing for Different Industries

Fashion and Apparel:

Personalizing Clothing with Digital Embroidery

Fashion designers have embraced embroidery digitizing to create

unique, custom designs that elevate their collections. From delicate floral

patterns on dresses to bold logos on streetwear, digitizing has made embroidery

a popular choice in the fashion world. The speed and precision of digital

embroidery have allowed designers to experiment with intricate patterns and

large-scale prints, pushing the boundaries of what’s possible in fashion.

Corporate Branding: Creating

Custom Logos with Precision

Embroidery digitizing has become a game-changer in corporate branding.

Businesses can now create highly detailed and consistent logos on everything

from hats and uniforms to office supplies. Custom embroidery offers a level of

sophistication and professionalism that printed designs

simply can’t match. With digitizing, companies can showcase their brand

in a high-quality, personalized manner.

Home Décor and Accessories:

Adding Unique Touches to Interiors

Embroidery digitizing isn’t just for clothing—it’s also made its mark

in home décor and accessories. Designers can create unique, embroidered accents

for pillows, blankets, and wall art, adding a personal touch to any space.

Whether it’s monogrammed towels or custom-designed bed linens, digitizing makes

it easy to produce high-end, customized home products.

Embroidery digitizing has transformed the craft, merging

technology with artistry to create limitless possibilities. With speed,

precision, and customization at your fingertips, the world of embroidery is

ready for innovation. Whether you're a hobbyist or a professional, digitizing

is the key to unlocking the full potential of your designs.