The Future is Here: Alternative to Screen Printing Revealed/Eagle Digitizing

Screen printing has long been a staple in the world of fabric and material decoration. It's a technique renowned for its durability and vibrancy, utilized in creating everything from t-shirts to posters. However, in an era where technology evolves at lightning speed, the traditional methods are often scrutinized and alternatives are sought. The quest for more efficient, cost-effective, and eco-friendly solutions has spurred the rise of digital printing technologies, reshaping the landscape of printing. For the top-notch vector art conversion, don't hesitate to get in touch with us.

Digital Printing

Digital printing is a revolutionary technique that involves transferring digital images directly onto various substrates. Unlike screen printing, which requires screens and stencils, digital printing operates through advanced printing devices and specialized inks.

Advantages of Digital Printing Over Screen Printing

Digital printing boasts several advantages. It allows for greater detail and precision, supports short runs without escalating costs, and eliminates the need for screens, making the setup process faster and more straightforward. The ability to easily adjust designs and incorporate complex color schemes without extensive preparation is another significant benefit.

Types of Digital Printing

Digital printing encompasses a variety of methods, including Direct to Garment (DTG), sublimation printing, heat transfer printing, vinyl cutting and transfer, and Direct to Film (DTF) printing. Each type offers unique benefits suited to different applications and materials.

Direct to Garment (DTG) Printing

Understanding DTG Printing

Direct to Garment (DTG) printing is a method where a digital printer applies ink directly onto the fabric, similar to how an inkjet printer works on paper.

How DTG Printing Works

DTG printers use water-based inks that are absorbed by the fibers of the garment, resulting in a soft and breathable print. The process involves pretreating the fabric, printing the design, and then curing the ink with heat.

Benefits of DTG Printing

DTG printing allows for intricate designs with a high level of detail and a wide range of colors. It is particularly beneficial for small batches and custom orders due to its quick setup and turnaround time.

Best Fabrics for DTG Printing

Natural fibers like cotton are ideal for DTG printing because they absorb water-based inks well. Blends and other natural fabrics can also be used, but the print quality might vary depending on the composition.

Sublimation Printing

The Sublimation Process Explained

Sublimation printing involves turning solid dye into gas without passing through a liquid state, which then embeds into the polyester fabric or polymer-coated substrate.

Ideal Materials for Sublimation

Sublimation works best on materials with a high polyester content or polymer-coated surfaces. This includes fabrics, ceramic mugs, and specially coated metals.

Advantages of Sublimation Printing

Sublimation printing offers vibrant, long-lasting colors that resist fading and peeling. It allows for full-color designs and all-over prints, making it ideal for creating custom apparel, promotional items, and home decor.

Popular Uses for Sublimation Printing

This method is widely used for sportswear, custom merchandise, interior decorations, and personalized gifts due to its durability and high-quality output.

Heat Transfer Printing

What is Heat Transfer Printing?

Heat transfer printing is the process of transferring a design to a substrate using heat and pressure.

Types of Heat Transfer Methods

There are several heat transfer methods, including inkjet transfers, laser transfers, and plastisol transfers. Each type uses different technologies and materials to achieve the desired print.

Pros and Cons of Heat Transfer Printing

Heat transfer printing is versatile and allows for detailed, full-color designs. However, it can be less durable than other methods, and the print might crack or peel over time, especially if not properly applied.

Applications of Heat Transfer Printing

This technique is popular for custom apparel, promotional items, and small-batch productions. It is ideal for on-demand printing and personalized products.

Vinyl Cutting and Transfer

Introduction to Vinyl Cutting

Vinyl cutting involves cutting designs out of colored vinyl sheets, which are then transferred onto the substrate using heat and pressure.

How Vinyl Transfers Work

The process includes designing on a computer, cutting the vinyl, weeding out the excess material, and then applying the design with a heat press.

Benefits and Drawbacks

Vinyl transfers are highly durable and have a clean, professional finish. However, they are less suitable for complex designs and are typically limited to solid colors.

Common Uses for Vinyl Transfers

Vinyl cutting is often used for creating custom t-shirts, sports jerseys, signage, and decals due to its durability and sharpness.

Direct to Film (DTF) Printing

What is DTF Printing?

Direct to Film (DTF) printing is a method where designs are printed onto a special film and then transferred to the fabric using heat and pressure.

DTF Printing Process Step-by-Step

The process involves printing the design onto a PET film, applying a hot melt adhesive powder, curing the adhesive, and then transferring the design onto the fabric with a heat press.

Why Choose DTF Printing?

DTF printing offers excellent color vibrancy and detail. It is versatile, suitable for a wide range of fabrics, and allows for both small and large runs without extensive setup.

Ideal Situations for DTF Printing

DTF printing is ideal for custom apparel, promotional items, and small to medium production runs where high-quality prints are required.

Eco-Friendly Alternatives

Water-Based Inks

Water-based inks are an eco-friendly option, reducing harmful emissions and waste. They penetrate the fabric for a soft feel and are ideal for light-colored garments.

Soy-Based Inks

Soy-based inks are another sustainable choice, offering vibrant colors with less environmental impact. They are used in various printing applications, including textiles and paper.

Benefits of Eco-Friendly Printing Options

Eco-friendly inks reduce the carbon footprint of printing processes and are safer for both workers and consumers. They provide a responsible alternative without compromising quality.

Comparing Eco-Friendly Inks to Traditional Inks

While traditional inks often contain harmful chemicals, eco-friendly inks are biodegradable and non-toxic, making them a better choice for sustainable practices.

Laser Printing

How Laser Printing Works on Fabrics

Laser printing on fabrics involves using a laser to bond toner or color to the material, creating a durable and precise design.

Advantages of Laser Printing

Laser printing offers high resolution and is capable of producing detailed images with sharp edges. It is efficient and suitable for both small and large batches.

Best Practices for Laser Printing

To achieve the best results, use materials specifically designed for laser printing and ensure the laser settings are correctly configured for the substrate.

Limitations of Laser Printing

Laser printing can be more expensive than other methods and is typically limited to smaller design areas. It may not be suitable for every fabric type.

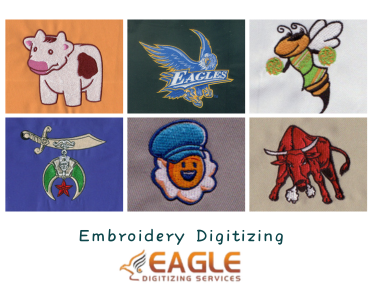

Embroidery

Embroidery as an Alternative

Embroidery is a traditional technique that uses threads to create raised designs on fabric, offering a tactile and luxurious finish.

Modern Embroidery Techniques

Modern embroidery machines are highly advanced, capable of creating intricate designs with multiple colors and textures, adding a touch of elegance to garments.

Benefits of Choosing Embroidery

Embroidery is highly durable and offers a sophisticated look. It is ideal for branding and logos on corporate apparel, uniforms, and promotional items.

Ideal Fabrics and Designs for Embroidery

Thicker fabrics like cotton, polyester, and blends are best suited for embroidery. Designs should be relatively simple to ensure clarity and precision.

Hybrid Printing Techniques

Combining Screen Printing and Digital Printing

Hybrid printing involves using both screen printing and digital printing techniques to capitalize on the strengths of each method.

Benefits of Hybrid Printing

Hybrid printing allows for high-quality, detailed designs with the durability of screen printing and the flexibility of digital printing. It is perfect for complex and colorful projects.

Examples of Successful Hybrid Prints

Successful hybrid prints often include intricate designs that require both detailed color gradients and the robust finish provided by screen printing.

Future of Hybrid Printing Technologies

Hybrid printing is likely to evolve further, integrating more advanced digital technologies to enhance efficiency and print quality.

Economic Considerations

Cost Comparison: Screen Printing vs Alternatives

While screen printing is cost-effective for large batches, digital alternatives offer lower setup costs and are more economical for small runs and custom orders.

Long-Term Savings with Alternative Methods

Alternative methods can lead to long-term savings through reduced labor, faster setup, and the ability to make quick changes without significant additional costs.

Scalability of Different Printing Methods

Digital printing methods scale easily, accommodating both small and large orders without the need for extensive reconfiguration, making them versatile for businesses of all sizes.

Quality and Durability

Comparing Print Quality

Digital printing methods often provide superior print quality with high resolution and vibrant colors. Screen printing remains unmatched in opacity and vibrancy on dark fabrics.

Durability Tests of Various Printing Methods

Durability varies by method; screen printing and embroidery are known for their longevity, while some digital prints may fade or crack over time if not properly cared for.

Maintaining Print Quality Over Time

Proper care, such as washing garments inside out and avoiding harsh detergents, helps maintain the quality of prints regardless of the method used.

Customization and Flexibility

Customization Capabilities of Alternatives

Digital printing methods excel in customization, allowing for unique designs, quick changes, and personalized products without significant downtime.

Flexibility in Design Changes

Digital printing supports on-the-fly design changes, making it ideal for businesses that require frequent updates and modifications.

Speed and Efficiency of Different Methods

Digital and hybrid methods offer faster turnaround times compared to traditional screen printing, enhancing overall efficiency in production.

Market Trends

Current Trends in the Printing Industry

The printing industry is witnessing a shift towards digital methods, driven by demand for customization, eco-friendliness, and efficiency.

Growing Demand for Digital Printing

Businesses and consumers alike are leaning towards digital printing for its versatility, quality, and quick turnaround times.

How Businesses are Adapting to New Technologies

Businesses are increasingly investing in digital printing equipment and training to stay competitive and meet the evolving demands of their customers.

Tools and Equipment

Essential Equipment for Digital Printing

Key equipment includes digital printers, heat presses, pretreatment machines, and software for design and color management.

Maintenance and Care of Printing Equipment

Regular maintenance, such as cleaning and calibration, is crucial to ensure the longevity and performance of printing equipment.

Upgrading from Screen Printing: What You Need

Upgrading involves investing in digital printing machines, learning new software, and possibly restructuring production workflows to accommodate new technologies.

Future of Printing Technologies

Innovations in Printing Technologies

Emerging technologies like 3D printing, nanotechnology, and advanced digital presses are poised to revolutionize the printing industry.

Predicting the Future of Digital Printing

Digital printing will likely continue to grow, driven by advancements in technology, increased demand for customization, and a focus on sustainability.

How to Stay Ahead in the Printing Industry

Staying ahead requires continuous learning, investing in new technologies, and remaining adaptable to market changes and customer preferences. Eagle Digitizing offers vector graphics services.

Exploring alternatives to screen printing reveals a landscape rich with innovative and efficient options. From digital printing to eco-friendly inks, each method offers unique advantages tailored to specific needs. By understanding the strengths and applications of these alternatives, businesses can make informed decisions that align with their goals and environmental considerations. As technology continues to evolve, embracing these advancements will be key to staying competitive and meeting the diverse demands of the market.