Embroidery Digitizing 101: The Ultimate Crash Course

What is Embroidery Digitizing?

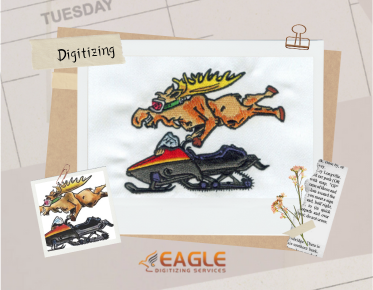

Embroidery digitizing is the process of transferringartwork into a digital format that an embroidery machine can read and

execute. This involves translating images or designs into a series of commands

that control the needle and thread, creating intricate patterns on fabric.

Unlike traditional embroidery, which is done manually, digitizing leverages

technology to achieve precision and efficiency.

Why Digitizing is a Game-Changer

Digitizing has transformed embroidery into a modern art form. It allows for intricate, repeatable designs that would be impossible or prohibitively time-consuming to create by hand. With digitizing, designs can be easily edited, resized, and customized, making it ideal for both large-scale commercial production and bespoke creations. The precision and speed offered by digitized embroidery open up new creative possibilities and business opportunities.

The

Basics of Embroidery Digitizing

Embroidery Digitizing vs.

Traditional Embroidery

Traditional embroidery relies on manual stitching, which can be

time-consuming and less consistent. Digitizing, on the other hand, uses

software to map out the stitches, ensuring uniformity and precision. This

method significantly reduces the time required to produce a design and allows

for easy replication.

Key Terms in Embroidery

Digitizing

●

Stitch Types: Different

methods of stitching, such as satin, fill, and run stitches.

●

Hooping: The process of

securing the fabric in a hoop to keep it taut during embroidery.

●

Stabilizer: A material

placed under the fabric to prevent stretching and distortion.

●

Density: The number of

stitches in a given area, affecting the texture and appearance of the

embroidery.

Essential Tools and Software for

Digitizing

To get started with digitizing, you'll need a computer, digitizing software, an embroidery machine, and various tools such as hoops and stabilizers. Popular software programs include Wilcom, Hatch, and Brother's PE-Design. These programs offer a range of features to help you create and refine your designs.

Choosing

the Right Software

Popular Embroidery Digitizing

Software

Several software programs stand out in the embroidery community.

Wilcom is renowned for its robust features and professional-grade quality.

Hatch is another favorite, known for its user-friendly interface. Brother's

PE-Design is ideal for those using Brother machines, offering seamless

integration.

Features to Look for in

Digitizing Software

When selecting software, consider features such as ease of use, the variety of stitch types, editing capabilities, and support for different file formats. Advanced features like auto-digitizing and 3D embroidery options can also be beneficial.

Preparing

Your Design for Digitizing

Selecting the Perfect Design for

Digitizing

Choose designs that are clear and have distinct lines and shapes.

Simple designs with bold outlines tend to digitize more effectively. As you

develop your skills, you can try out more intricate patterns.

Understanding Design Complexity

and Its Impact

Complex designs with intricate details require more time and skill to

digitize. They also result in higher stitch counts, which can affect the

fabric's integrity and the machine's performance. Simplifying designs can help

ensure better results.

Tips for Simplifying Complex

Designs

Break down intricate designs into smaller sections and focus on key elements. Use fewer colors and avoid overly detailed patterns. Simplifying the design not only makes digitizing easier but also enhances the final embroidery's clarity and impact.

Scanning

and Vectorizing Your Design

How to Scan Your Artwork

Use a high-resolution scanner to capture your artwork. Ensure the

image is clear and free of shadows or distortions. Save the file in a format

compatible with your digitizing software, such as JPEG or PNG.

The Importance of Vectorizing in

Digitizing

Vectorizing converts raster images (composedof pixels) into vector images (composed of paths). This process ensures

that the design can be scaled without losing quality and allows for more

precise control over the stitching.

Tools for Vectorizing Your

Design

Software like Adobe Illustrator or CorelDRAW can be used to vectorize your designs. These tools offer advanced features for refining and perfecting your vector images before importing them into your digitizing software.

Setting

Up Your Digitizing Workspace

Organizing Your Work Area

A well-organized workspace is essential for efficient digitizing.

Arrange your tools and materials within easy reach, and keep your computer and

embroidery machine in close proximity to streamline the workflow.

Essential Hardware for

Digitizing

In addition to a powerful computer and embroidery machine, invest in a

good-quality scanner and graphics tablet. A graphics tablet can provide more

precise control when drawing or editing designs.

Creating an Efficient Workflow

Establish a step-by-step process for digitizing, from scanning and vectorizing to editing and stitching. Regularly save your work and backup files to prevent data loss. An efficient workflow helps maintain consistency and reduces errors.

Digitizing

Your First Design

Step-by-Step Guide to Digitizing

- Import your

vectorized design into the digitizing software.

- Choose the

appropriate stitch types for different parts of the design.

- Set the

stitch density and length based on the fabric type.

- Add any

necessary underlays to stabilize the embroidery.

- Preview the

design to check for errors or adjustments needed.

Common Mistakes to Avoid

Avoid overly dense stitching, which can cause the fabric to pucker.

Ensure proper alignment of the design elements and check for any gaps or

overlaps in the stitches.

Tips for Perfecting Your First

Design

Take your time to experiment with different settings and stitch types. Perform test runs on similar fabrics to identify and correct any issues. Use high-quality threads and needles to achieve the best results.

Understanding

Stitch Types

Overview of Different Stitch

Types

●

Satin Stitch: Ideal for

outlines and text.

●

Fill Stitch: Used for

covering large areas.

●

Run Stitch: Suitable for

fine details and outlines.

●

Triple Stitch: Provides extra

durability for frequently washed items.

When to Use Each Stitch Type

Choose satin stitches for smooth, glossy finishes and fill stitches

for dense, textured areas. Run stitches are best for intricate details, while

triple stitches are useful for areas requiring added strength.

Combining Stitch Types for

Effect

Mixing different stitch types can add depth and dimension to your design. For example, using a combination of satin and fill stitches can create a striking contrast and make certain elements stand out.

Choosing

the Right Stabilizers

Importance of Stabilizers in

Embroidery

Stabilizers provide support and prevent the fabric from stretching or

distorting during embroidery. They ensure that the design maintains its shape

and integrity.

Types of Stabilizers and Their

Uses

●

Tear-Away

Stabilizers: Easy to remove, ideal for stable fabrics.

●

Cut-Away

Stabilizers: Provide permanent support, suitable for stretchy fabrics.

●

Water-Soluble

Stabilizers: Dissolve in water, perfect for delicate fabrics or lacework.

How to Apply Stabilizers

Correctly

Hoop the fabric and stabilizer together to ensure they stay in place.

Make sure the stabilizer is taut and free of wrinkles. For best results, choose

the appropriate stabilizer based on the fabric type and design complexity.

Adjusting

Stitch Density and Length

The Role of Stitch Density in

Embroidery

Stitch density is the number of stitches in a particular area. It

affects the embroidery's texture, durability, and appearance. Too much density

can make the design stiff, while too little can result in gaps.

How to Adjust Stitch Density and

Length

Use your software's settings to modify stitch density and length. Test

different configurations on sample fabric to find the optimal balance.

Adjustments may be necessary based on the fabric type and design intricacy.

Balancing Density for Different

Fabrics

Denser fabrics can handle higher stitch densities, while lighter

fabrics require lower densities to avoid damage. Consider the fabric's weight

and weave when setting the stitch density and length.

Color

Management in Digitizing

Selecting the Right Colors for

Your Design

Choose colors that complement each other and match the intended look

of the design. Consider the fabric color and ensure the thread colors stand out

against it.

Tools for Accurate Color

Matching

Many digitizing software programs include color palettes that

correspond to popular thread brands. Use these tools to ensure accurate color

matching and consistency across designs.

Tips for Managing Color

Transitions

Smooth color transitions by blending stitches and using gradient

techniques. Avoid abrupt changes in color, which can create harsh lines and

disrupt the design's flow.

Testing

Your Digitized Design

Why Test Runs are Crucial

Test runs allow you to identify and correct any issues before

embroidering the final design. They help ensure the design looks as intended

and the stitches are properly aligned.

Interpreting Test Run Results

Examine the test embroidery for any flaws, such as misaligned stitches

or color discrepancies. Use the results to make necessary adjustments to the

design or settings.

Making Necessary Adjustments

Based on the test run, modify the stitch density, length, or type as

needed. Adjust the color sequence or correct any alignment issues to perfect

the design.

Advanced

Digitizing Techniques

3D Puff Embroidery

This technique adds a three-dimensional effect to the design by using

foam under the stitches. It creates a raised, tactile surface, making the

design stand out.

Applique Digitizing

Applique involves stitching fabric pieces onto the base fabric.

Digitizing for applique includes creating placement lines, tack-down stitches,

and finishing stitches to secure the fabric pieces.

Creating Intricate Patterns

Advanced software features allow for the creation of intricate

patterns and textures. Experiment with different stitch effects and layering

techniques to add complexity and visual interest to your designs.

Embroidery

File Formats

Common File Formats in

Embroidery

●

DST: Widely used in

commercial embroidery machines.

●

PES: Commonly used

with Brother embroidery machines.

●

EXP: Compatible with

many industrial machines.

●

JEF: Used with

Janome embroidery machines.

Converting Between Formats

Most digitizing software allows for easy conversion between different

file formats. Ensure the converted file maintains the design's integrity and

stitch properties.

Best Practices for Saving Your

Files

Save your designs in multiple formats to ensure compatibility with various machines. Keep backup copies and organize your files for easy access and retrieval.

Transferring

Your Design to the Embroidery Machine

How to Transfer Files to Your

Machine

Transfer files using USB drives, memory cards, or direct computer

connections. Check that the file format is compatible with your embroidery

machine.

USB, Wi-Fi, and Other Transfer

Methods

Some modern machines offer Wi-Fi connectivity, allowing for wireless

file transfers. USB drives and memory cards remain reliable and widely used

methods.

Ensuring Compatibility with Your

Machine

Verify that your machine can read the file format and check for any specific requirements or limitations. Test a small section of the design to confirm compatibility.

Embroidering

Your Digitized Design

Setting Up Your Machine for

Embroidery

Load the digitized design into the machine, select the appropriate

settings, and ensure the fabric and stabilizer are securely hooped. Perform a

quick test to verify everything is set up correctly.

Monitoring the Embroidery

Process

Keep an eye on the machine as it embroiders to catch any issues early.

Check for thread breaks, fabric movement, or any other problems that might

arise.

Finishing Touches and Cleanup

When the embroidery is finished, carefully take out the fabric from the hoop. Trim any loose threads and remove any excess stabilizer. Inspect the design for any final adjustments or touch-ups.

Embroidery digitizing transforms artwork into intricate, machine-embroidered designs. It combines technology with creativity, offering precision and efficiency. Understanding the basics, choosing the right tools, and practicing advanced techniques are essential for mastering digitizing.

Embarking on your digitizing journey can be immensely rewarding. With

the right knowledge and tools, you can create beautiful, professional-quality

embroidery designs.